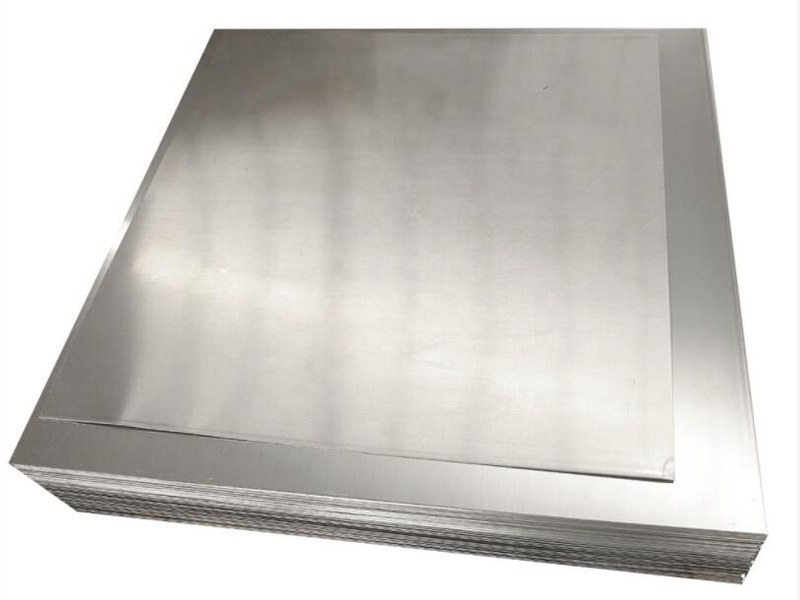

3005 aluminum sheet belongs to 3 series Al-Mn alloy with Mn content between 1.0-1.5, and 3003, 3004 aluminum sheet belongs to rust-proof alloy with strong corrosion resistance.

Similarly,3005 aluminum sheet is also a non-heat-treated alloy, which is cold-processed to improve its mechanical properties.

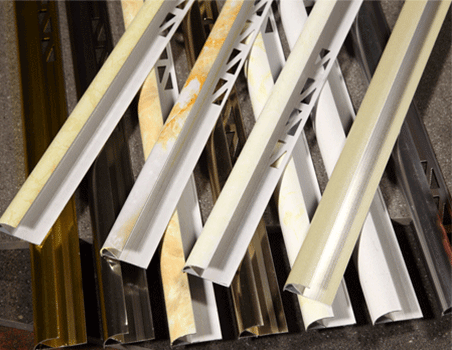

However, the strength of 3005 aluminum is higher than both of them. Among them, it is about 20% stronger than 3003 aluminum sheets. In addition, the the3005 aluminum sheet is also excellent in formability, solubility, and anodic oxidation.

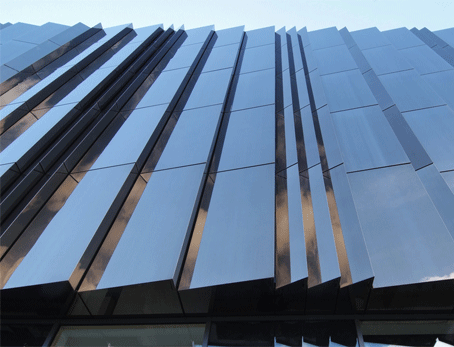

Therefore, according to these 3005 aluminum properties, different types of aluminum alloys of 3005 can be widely used in air conditioning, refrigerator, car bottom, the ocean, and other humid environments, but also often used in building materials, color aluminum sheets, etc. As a professional manufactuer of 3005 aluminum plate, Lichen can provide you with high-quality 3005 aluminum plate. Welcome to contact us.

English

English  日本語

日本語  한국어

한국어  français

français  Deutsch

Deutsch  Español

Español  العربية

العربية  tiếng việt

tiếng việt  ไทย

ไทย